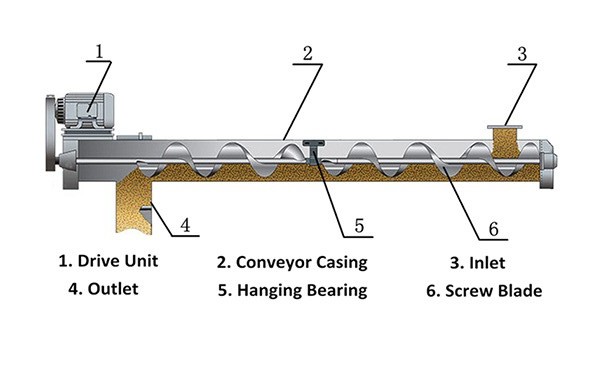

There are many parameters affecting the working of

level spiral conveyor, including conveying capacity, filling rate, screw pitch, screw shaft speed, screw blade diameter, etc., in particular, some of the main parameters, which have a very big impact on the production efficiency, service life and work performance when horizontal conveying of the auger conveyor machine.

1.Delivery capacity

The delivery volume is a very important indicator of the horizontal spiral conveying capacity. The capacity is generally designed according to the production needs, but it is also closely related to a series of parameters such as the fill factor, screw pitch, and screw shaft speed.

When the material is conveyed in the

horizontal screw feeding equipment, although the volume occupied by the screw shaft has a certain influence on the conveying amount, the influence is very small. Therefore, the influence of the volume occupied by the screw shaft on the material conveyance is ignored here.

2.Screw shaft speed

The rotation speed of the screw shaft has a great influence on the conveying volume of the horizontal screw feeder conveyor. In general, the greater the speed of the screw shaft, the greater the amount of transport of the

horizontal auger transporting conveyor, and the smaller the speed of rotation, the smaller the amount of conveying.

However, the rotation speed of the screw shaft cannot be increased without limit, because when the rotation speed exceeds a certain size, the material will be tumbling due to too much centrifugal force, and the material just happens to rotate when the speed is the limit speed of the screw shaft. .

It is necessary to ensure a certain screw speed to keep the material transporting without such tumbling,.

As a professional

conveyor spiral machine manufacturer, PK Machinery always provide superior product quality and considerate service to our client, further information, please browse:

www.pkmachinery.com