Bucket elevator

Bucket elevator has significant advantages with a large capacity, stable and reliable operation, long service time and others, the main performance and parameters are in line with JB3926 - 85 "vertical bucket elevator" (the standard equivalent to the international standards and advanced foreign Standard), the traction ring chain is accord with MT36 - 80 "mining ring chain with high strength", the bucket elevating machine is suitable for conveying powder, granular and small non-abrasive and small abrasive materials such as: coal, cement, stones, sand, clay, ore, etc., because bucket elevator traction mechanism is a circular chain, allowing the delivery of higher temperature materials (material temperature does not exceed 250 °C). The conveying height is up to 40 meters, maximum height 80 meters.

The endless chain used in the continuous discharging bucket elevator is strung between the head assembly and the tail assembly and operates in the free-standing casings.

Multiple buckets mounted on the chain are equally spaced for the transport of material in the vertical direction.

Unlike other types of

bucket hoisting equipment, continuous discharging hopper elevator is not suitable for scooping material from the feeding hopper. Instead, the material is fed directly into the bucket (for feeding) by the raised feeding chute.

The gap between the charging chute and the bucket is designed to a minimum, which reducing the amount of material falling into the bottom casing of the machine.

Residual material must be constantly removed to prevent buckets and materials stacked on the feed box from interfere with each other.

Interference between the bucket and the material can lead to excessive wear of the buckets and in extreme cases can cause the bucket elevator to stop operating.

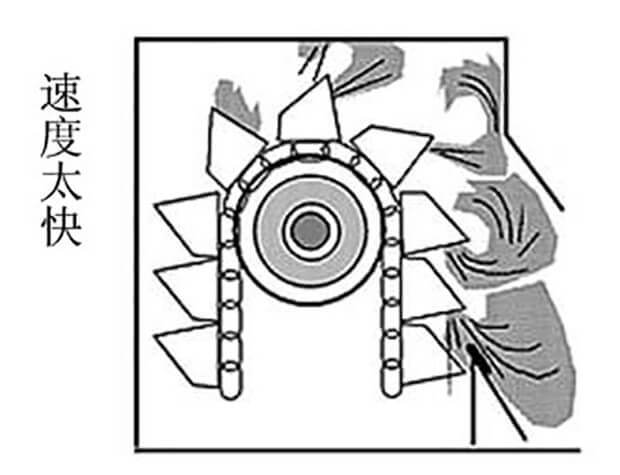

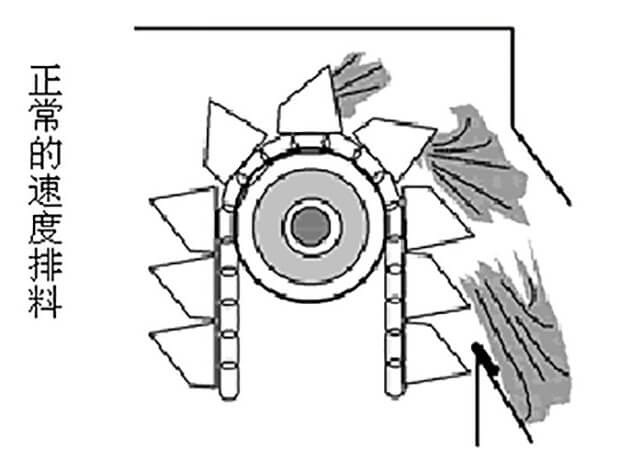

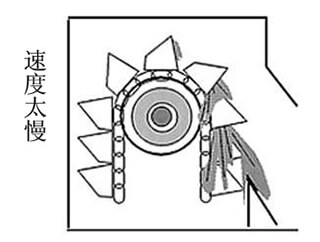

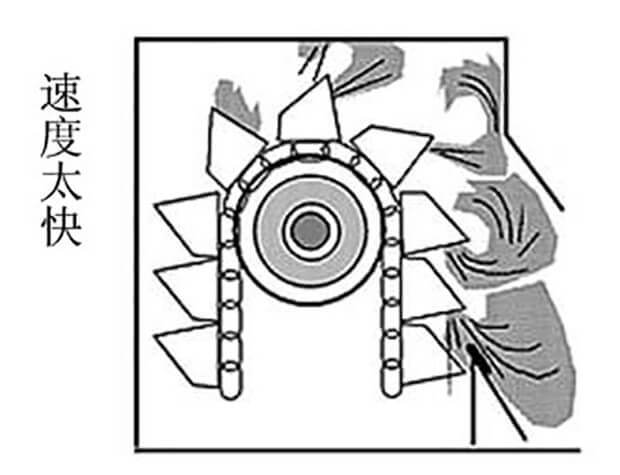

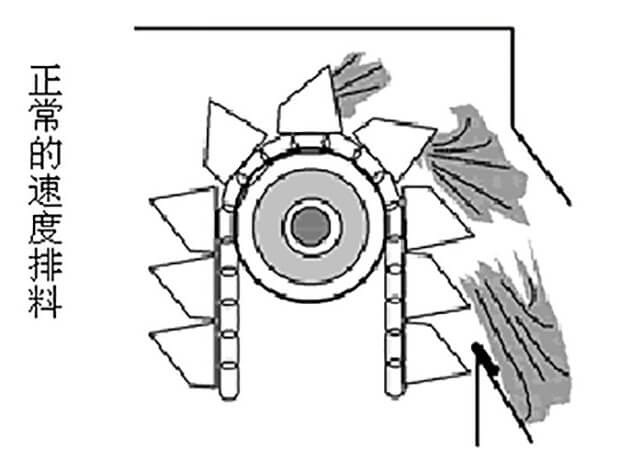

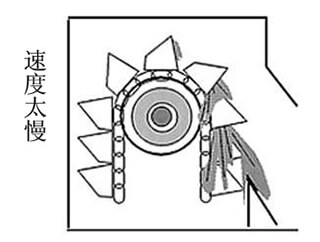

When the bucket passes through the upper sprocket, the material is discharged due to gravity and centrifugal forces.

When the bucket moves forward over the head assembly, the material slides out from the bucket and hits the front of the next bucket. The flange of the next bucket acts as a slider that guides the material to the discharge chute.

When conveying powdered materials, in order to improve the discharging efficiency of the bucket lifter, the lower walls of each bucket are drilled with holes. These holes allow air to escape when the hopper is lifted; and the air can enter the buckets when the material is discharged.

This design ensures that the material can be filled in the buckets and all the materials discharged from the buckets.

As a professional

bucket elevator equipment manufacturer, PK Machinery always provides superior product quality and considerate service to our client, further information, please browse:

www.pkmachinery.com

Bucket elevator has significant advantages with a large capacity, stable and reliable operation, long service time and others, the main performance and parameters are in line with JB3926 - 85 "vertical bucket elevator" (the standard equivalent to the international standards and advanced foreign Standard), the traction ring chain is accord with MT36 - 80 "mining ring chain with high strength", the bucket elevating machine is suitable for conveying powder, granular and small non-abrasive and small abrasive materials such as: coal, cement, stones, sand, clay, ore, etc., because bucket elevator traction mechanism is a circular chain, allowing the delivery of higher temperature materials (material temperature does not exceed 250 °C). The conveying height is up to 40 meters, maximum height 80 meters.

Bucket elevator has significant advantages with a large capacity, stable and reliable operation, long service time and others, the main performance and parameters are in line with JB3926 - 85 "vertical bucket elevator" (the standard equivalent to the international standards and advanced foreign Standard), the traction ring chain is accord with MT36 - 80 "mining ring chain with high strength", the bucket elevating machine is suitable for conveying powder, granular and small non-abrasive and small abrasive materials such as: coal, cement, stones, sand, clay, ore, etc., because bucket elevator traction mechanism is a circular chain, allowing the delivery of higher temperature materials (material temperature does not exceed 250 °C). The conveying height is up to 40 meters, maximum height 80 meters.