Circular Vibrating Screen is a kind of new and highly effective vibrating screen which can be designed with multiple layers.

Following mentioned are some useful points for circular vibrating separator maintenance, hope they are helpful.

1. Always keep the

circular vibrating screen in a clean and sanitary working environment.

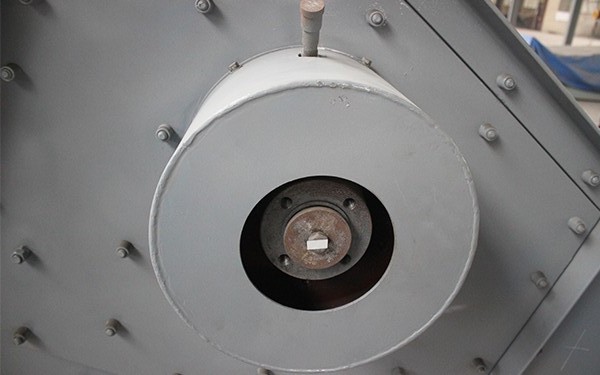

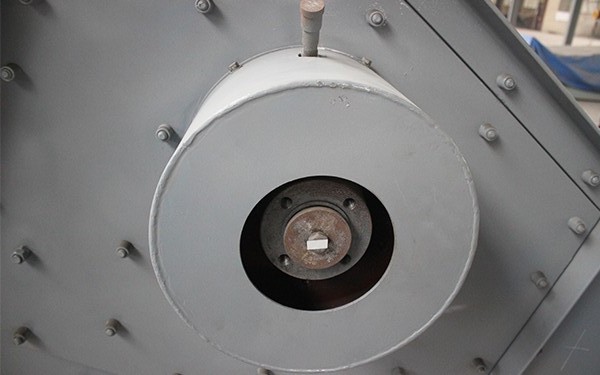

2. The bearing on motor both ends should be lubricated with anti- high temperature lubricating grease.

3. Check flange bolts on motor both sides, please make sure no loose phenomenon occurs of the bolts which fix the mesh as well as the support connecting bolt .

4. The circular vibration screen should be maintained every half year.

A. Clean the motor and add grease for all lubricating points.

B. Check the abrasion condition of screen mesh, if any damage , please maintain and replace timely.

5. The

circular vibrating screen should be maintained and repaired every year.

A. Open the motor terminal box ,check the insulation between the wires and clean the dust.

B. Add grease on all lubricating points.

C. check each part of the circular vibrating screen and abrasion condition of screen mesh, if any damage please maintain and replace timely.

E. After finishing all the work, a trial run is also required.

Further information please click:

www,pkmachinery.com