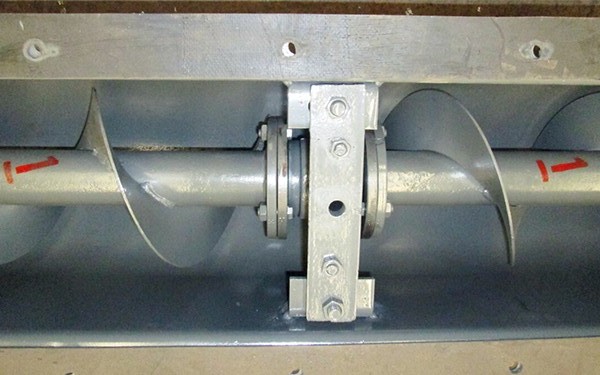

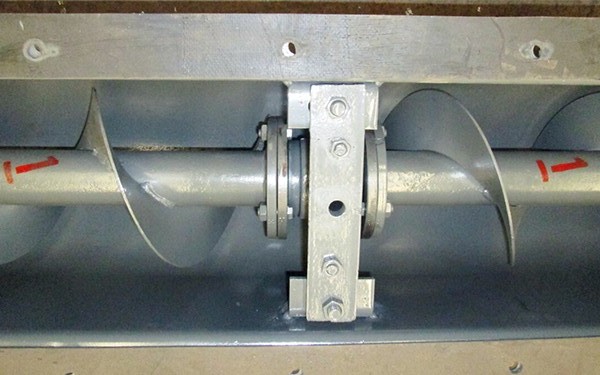

Screw conveyor is a conveying equipment which moves the material with the help of blade rotation. If the conveyor length is too long, the screw shaft will collapse, so we need to install the hanger bearing for long shaft to avoid the excessive abrasion due to the shaft collapse, that’s why the hanger bearing is the most easily wear part.

The

screw feeder conveyor service life depends on the hanger bearing service life, after hanger bearing break, the screw conveyor will not work. The hanger bearing is made of abrasion-resistant alloy, we need to add the lubricating oil before conveyor working in order to prevent the excessive friction causing a huge abrasion to the hanger bearing, as well as unnecessary losses.

Besides, normal working of hanger bearing can promise the coaxiality, resistance and noise of the

trough screw conveyor and keep it in a good working condition with a better using effect and longer service life at same time.

Further information, please click:

www.pkmachinery.com