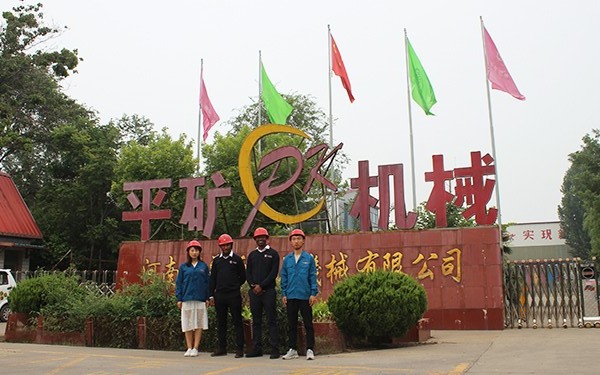

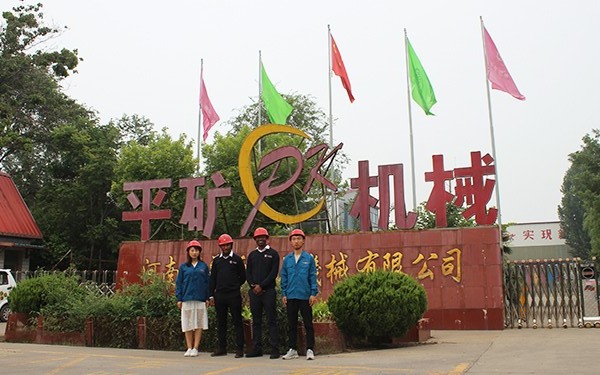

Last Wednesday, clients from South Africa visited PK Machinery for the purpose of discussing and inspecting roller production line, meanwhile, this visit was ended in a satisfactory way.

Clients’ company is a mining service company that provides conveyor belt maintenance and solutions in the mining sector, which includes belt conveyor splicing, pulley lagging, idlers, rollers, skirting and

belt conveyor supply. The purpose of this visit is to discuss and inspect our

roller production line.

Our technician introduced the roller production in detail, which includes seven sets of equipment: Automatic roller pipe feeding machine, Automatic Cutting and Beveling Machine Tool for Steel Pipes, Automatic Machine Tools for Both Ends Hole Turning, Automatic CO2 Gas-shielded Dual-torch Auto-welding Machine, Milling Shaft End Centering And Beveling Machine Tool, Shaft Both End Flat and Groove Milling Machine and Automatic Machine Tool for Conveyor Roller Press Assembly. After the introduction, clients had a tour to our workshop, they were quite happy with our equipment and they would first start the order with conveyor roller.

Conveyor roller

Conveyor roller is an important component of belt conveyor, which is used to support belt and bulk material of conveyor effectively . Conveyor roller consists of shell, shaft, bearing, housing, seals and snap ring. According to China national standards, diameter are Ф76,Ф89,Ф108,Ф133,Ф159 etc. If you have any interest of our conveyor rollers, please feel free to contact us.

Further information, please click:

www.pkmachinery.com