The structural analysis and application of cement screw conveyor

1.Application

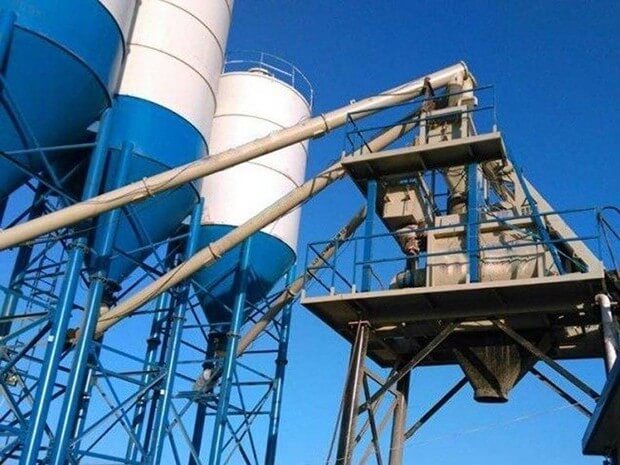

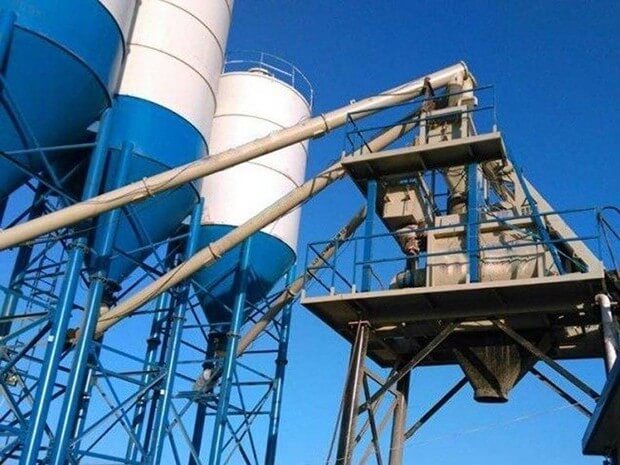

Screw conveyor is mainly used for conveying cement, fly ash, fine sand powder and fine granular dry material. Commonly used in mixing stations, cement, mining equipment.After long - term improvement, screw conveyor mainly has the following characteristics: A. Made of high-quality imported high-strength wear-resistant steel continuous spiral blade, forming the pitch error is less than 5mm and blade surface is smooth, ensuring the uniformity of material handling, stability, thus ensuring the accuracy of material measurement repeatability.

B.Continuous spiral blade made of cold-hardened surface cold-rolled treatment, hardness and wear resistance than ordinary blades to increase about double the hardness of up to HB240.

C.Front and hind spiral blade for the sparse, dense two pitch, effectively prevent plugging. Commonly known as "eat less, spit fast." Made of high-precision blades to ensure that the material is full of tube delivery, users from the screw conveyor inlet canvas flat suction situation can determine the advantages and disadvantages of screw conveyor.

D.The inner shaft of the screw conveyor is provided with a middle hanging bearing in a certain distance to support the rotating of the inner shaft. The middle hanging bearing is made of cast steel or cast aluminum, and the single cantilever supporting body makes the gap between the blades of the front and the hind joint smaller , The material flow cross section is maximized, so that the flow is smooth and unhindered.

E.Spiral conveyor feed port and cement warehouse port connection is divided into: the ball hinged flange rigid connection and waterproof canvas with flexible connection in two forms. The frequency of visual equipment disassembly determines the interface form.

F.The special design of the front support body enables the inner screw shaft to work under tension during normal operation. The tension force is borne by the thrust bearing in the front supporter to prevent the reducer and the middle suspension shaft seat from being compressed to prevent the bolt shaft from being pressured swallowing phenomenon.

2.Structure and working principle

LS series screw conveyor structure sequence: motor, gear box, the input section assembly, the middle section and intermediate support body assembly, the output section assembly, the front bearing assembly, oil lubrication system, accessories for the cable, Connecting canvas cover, hanging wire rope and accessories and so on. Screw conveyor sections are used between the flange connection, the connection adopt the seal. Lubrication system Lubricating oil system through the oil pipe through the brass, pipe fittings pressed into the lubrication required, the front bearing body grease from the front end of the nozzle.

During normal work, driven by the motor to the gearbox power screw shaft rotation, the material pushed by the spiral blade to the front discharge port.

When the screw machine is used to test the cables, observe whether the top shaft of the screw machine is turning properly. Screw conveyor can be used more wire rope hanging, can also be used to support the stent, but erection must ensure the straightness of the screw conveyor. Screw conveyor are generally added in the air, once the equipment is installed, all the parts in place, the equipment used in the event of a problem requiring maintenance, disassembly, maintenance will be very troublesome, so in the choice of the product must be in the structure principle has the correct screening. In addition: The general screw conveyor supporting the use of complete sets of equipment for manufacturers, as an accessory screw conveyor stock, but for different users or different occasions require users to provide delivery length (or import ramp length), elevation, by the manufacturers customized according to user requirements.

further information, please browse:

www.pkmachinery.com

1.Application

1.Application