The choice of conveying chain and scraper for scraper conveyor

Scraper conveyor machineis widely used in ports, grain depots, oil, flour, alcohol, brewing, feedstuff, chemical and other industries, this machine is acontinuous transmission equipment, with the help ofthe movement of the scraper chain which is consist in the closed casings, used to transport powder materials, granular materials, massive materialand other bulk materialunderthe acting force of bulk material internal frictionand side pressure characteristics.The machine could transport materials horizontally, inclined and even vertically, the scraper chain is buried in the materialin operation, so it is called buried scraper conveyor.

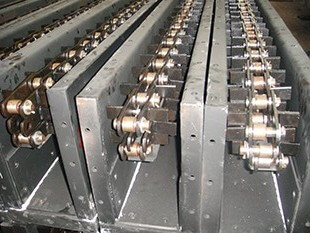

The choice of conveying chain for scraper conveyor

According to the requirements of the conveying length and the conveying capacity, selecting the appropriate scraper chain to calculate the tension, checking the allowable load of the chains, also selecting the appropriate pitch, the structure of the chain, the width and thickness of the chain plate, and then calculating the length of the scraper chain.

As we all know, the scraper chain is the main working part of the

buried chain conveyor machine, the conveying effect of the material has a great relationship with its type, and it is the load bearing structure of the buried scraper conveying equipment. The choice of the chain depends mainly on the maximum tension of the conveying chain, and also takes the characteristics of the materials into consideration, such as theroller chain should not be used for the powder materials, but it is prefer used for conveying materials which are easy to floating chain.

.jpg)

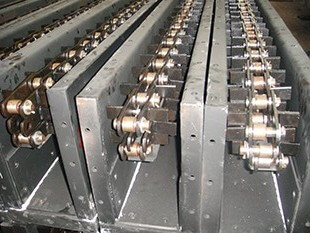

The choice of scraper for scraper conveyor

The choice of the scraper type for the En-masse conveyor depends primarily on the characteristics of the material and is also limited by the structure of the buried scraper conveyor itself.

When transporting the general materials, it is often use the scraper type with simple structure; and also choose a more simple structure to reduce the adhesionofmaterials on the scraper, when transportinglarger sticky material, so that it is easy discharge and cleaning;

For the suspended materials, and materials with large flowability, it should be used in the scraper typewith the more complexstructure;

When transporting materials with largedensity, especially the casing width is large, it should be used the scrapertype with inclined strut support to ensure its strength and rigidity;

In order to reduce its breaking rate, improve the wear resistance of the scraper, reduce the weight and the noise, it couldadopt the engineering plastics scraper;

When transportingfinepowder or powder materialswhichwithlargebulk density, high proportion of large particle and high water content horizontally, also the conveying distance is too long, there will be "materialblocking", which will often make the scraper chain floating on the materials, that is, "floating chain" phenomenon,

We can weld the scraper on the chain under the inclination of 7°-8°with the opposite runningdirection of the chain,the movement resistance can produce vertical force with downward pressure, so that the running of scraper chain closes to the casings bottom, to avoid "floating chain" phenomenon.

As a professional scraper conveying machine manufacturer, PK Machinery always provide superior product quality and considerate service to our client, further information, please browse:

www.pkmachinery.com

.jpg)