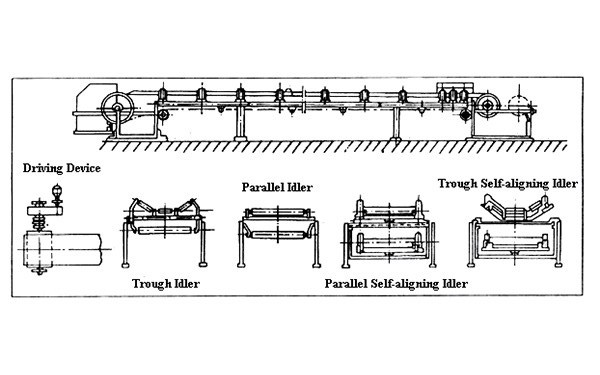

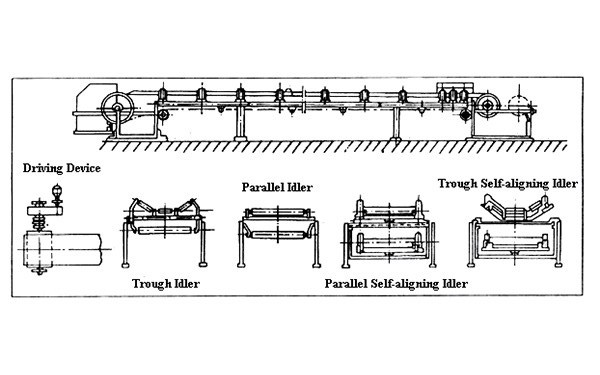

Long distance belt conveyor consists of driving device, transmission roller, reversing roller, conveyor belt, upper and lower roller sets, tensioning device ,cleaner, feeding device, unloading device, supporting member, safety protection device. What’s the correct belt conveyor installation steps?

1.Install the rack.Start the installation from the nose, then install the intermediate sections in the sequence and finally install the tailstock. Before installing the rack, first pull the center line over the entire length of the conveyor. Because keeping the center line of the conveyor in a straight line is an important condition for the normal operation of the conveyor, when installing each section of the rack, must be aligned with the center line,frame tolerance of the center line, per meter length is±0.1mm. However, the error in the center of the rack over the entire length of the conveyor must not exceed 35mm. Once all sections have been set up and aligned, each block can be connected.

2.Install the drive device. When installing the

rubber belt conveyor drive device, care must be taken to keep the drive shaft of the belt conveyor so that the center of the width of the drive roller coincides with the centerline of the conveyor. The axis of the reducer is parallel to the drive axis. At the same time, all shafts can be in the range of 0.5-1.5mm depending on the width of the conveyor. At the same time when the drive device is installed, a tension device such as a tail wheel my be installed, and the roller axis of the tension device should be perpendicular to the center line of the belt conveyor.

3.Install roller. After the racks installation, transmissions and tensioning devices are installed, the roller brackets of the upper and lower idler rollers can be installed so that the conveyor belt has a slowly reversing bending arc. The spacing between the roller brackets of the bending section is 1 of the normal roller rack spacing. 1/2 to 1/3.After the roller is installed,it should be flexible and light.

4.Fix the rack to the base or floor.After the

belt conveyor machine is fixed,feeding and discharging devices can be installed.

5.When the conveyor belt is installed, the conveyor belt is first to be laid on the idler roller of the idle section, and after enveloping the driving roller, the conveyor belt is placed on the idler roller of the heavy load section.

6.After the belt conveyor is installed, an idle test machine is required. In the idle test machine,it is necessary to pay attention to whether there is deviation in the operation of the conveyor belt,the operating temperature of the driving part, the movement of the idler during operation, the degree of contact between the cleaning device and the guide plate and the surface of the conveyor belt,etc. The necessary adjustments are made and all parts are normal before the load tester can be operated.

Henan Pingyuan mining machinery Co, Ltd is a manufacturer specializing in the production of belt conveyors.More details click

www.pkmachinery.com.