Sieve plate is an important part of the

vibrating screening machine to finish the screening process. Each vibrating sieve must be equipped with a suitable sieve plate.

The various characteristics of the material, the different structures of the sieve plate, the materials and various parameters of the

vibration shaker all affect the screening capacity, efficiency, and life of the shaker. Different materials and different applications should use different sieve plates, in order to achieve the best screening results.

Sieve plates should have sufficient strength, high open porosity and should be difficult to plug holes as well as other properties. When the vibrating screen runs, different size materials are separated to achieve the purpose of classification under the action of the vibration force.

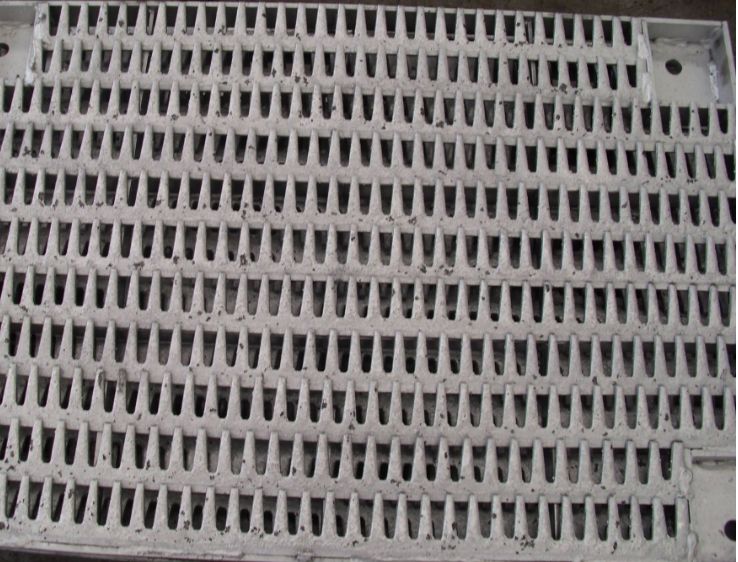

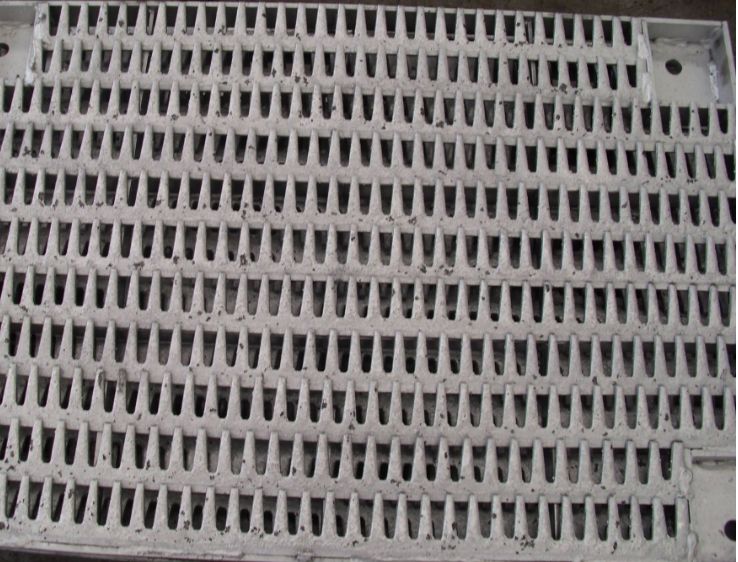

Comb sieve plate:

Comb sieve plate has the outstanding features of non-blocking and high screening efficiency. It is suitable for sintering, clinker, coke and various raw ore, such as coal, metallurgy, chemical industry, and other dry materials with high hardness and heavy weight. The sieve plate can have different service life depending on the selected material.

According to different materials,

vibration separator sieve plates can be divided into: new wear-resistant alloy sieve plate, high wear-resistant alloy sieve plate, stainless steel casting sieve plate, spray sieve plate, welded sieve plate, wear-resistant cast steel sieve plate, ordinary sieve plate.

Wire woven mesh sieve:

The woven wire mesh screen is woven with crimped metal wire, and the screen holes are square or rectangular. Its advantages are: light weight, high open rate; and in the screening process, due to the metal wire has a certain degree of elasticity, and for high-frequency vibration, so that the fine particles stick to the wire off, thereby improving the screening efficiency. It is applicable to the classification of medium and fine-grained materials. However, its disadvantage is its short service life.

Wire woven mesh screen surface rough points and fine holes. The material used for the rough-hole woven screen is low-carbon steel wire, spring steel wire and stainless steel wire. The mesh size is generally 4-125mm, and the wire diameter is 1.6-12.5mm.

Fine-hole woven mesh is generally made of low-carbon steel, brass, tin, tin bronze, and stainless steel, and is woven with a special weaving machine. Its open rate is: 36%-80%, mesh size: 0.03-16mm. Applicable sieve angle: 18°-30°.

As a professional

vibrating sieving machine manufacturer, PK Machinery always provide superior product quality and considerate service to our client, further information, please browse:

www.pkmachinery.com